TSX® Dental Implant

TSX dental implants exceed expectations in immediacy, leveraging an extraordinary combination of clinically proven features.

Going to the Xtreme for Primary Stability and Peri-Implant Health

The TSX Implant incorporates several design elements with a long history of clinical use established by Screw-Vent® and TSV Implants. The origins of these design features and understanding of their clinical rationale and evidence provide historical context for the evolution of the TSX Implant.

TSX Dental Implant Benefits

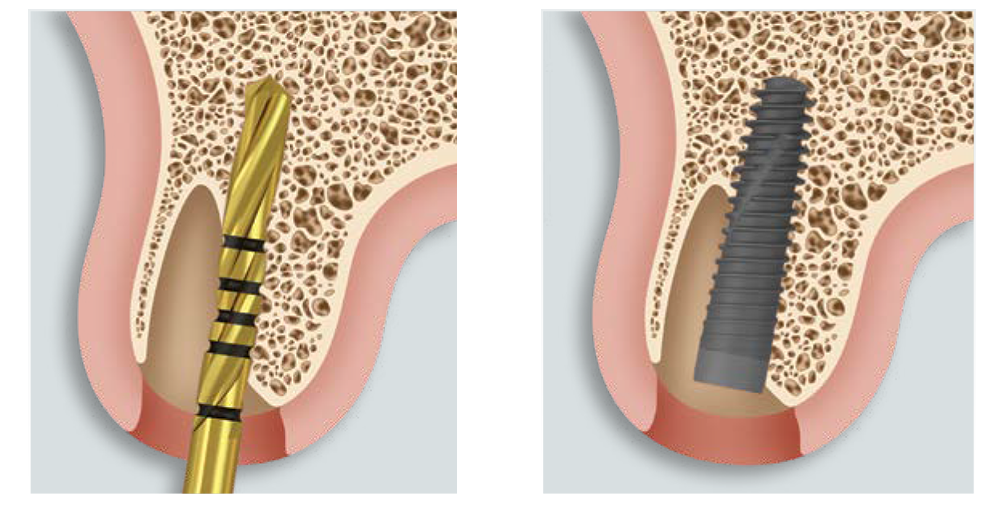

Taking Xtraction Site Stability to the Next Level

TSX Apical Stability Results1*

- > 35 Ncm apical torque in TSX extraction protocol

- 25% more dental implant surface area in contact with bone upon insertion than the TSV Implant (in TSX extraction protocol)

(Data from in vitro testing engaging only the apical 4mm of the dental implant; untapped averages).

Placement Predictability

- Designed to follow the drilled osteotomy - Unlike some very aggressive dental implants that can track off the desired course during placement, the TSX Dental Implant is not designed to change direction during seating, aiding in placement predictability.

TSX Dental Implant Advantages

Supporting Peri-implant Health and Crestal Bone Maintenance

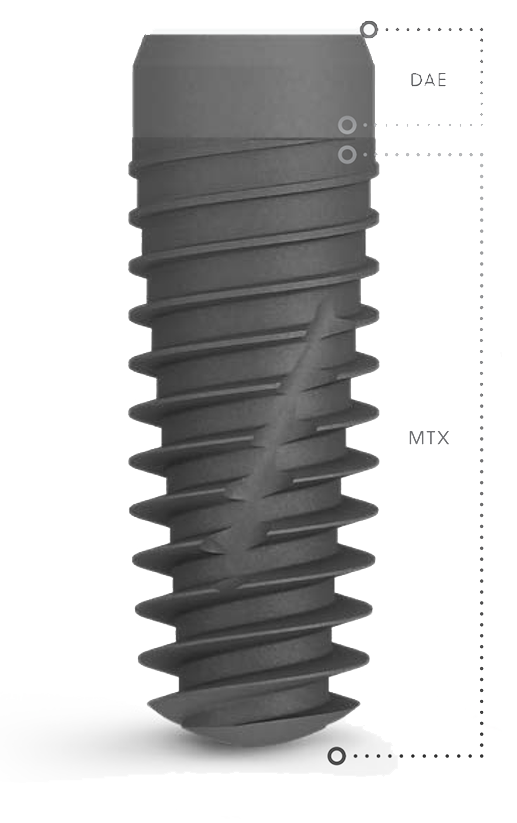

Contemporary Hybrid Surface

- The TSX Dental Implant leverages decades of clinical history in its combination of surface technologies shown to balance peri-implant needs in the coronal and sub-coronal regions.1-5, 12-14 *

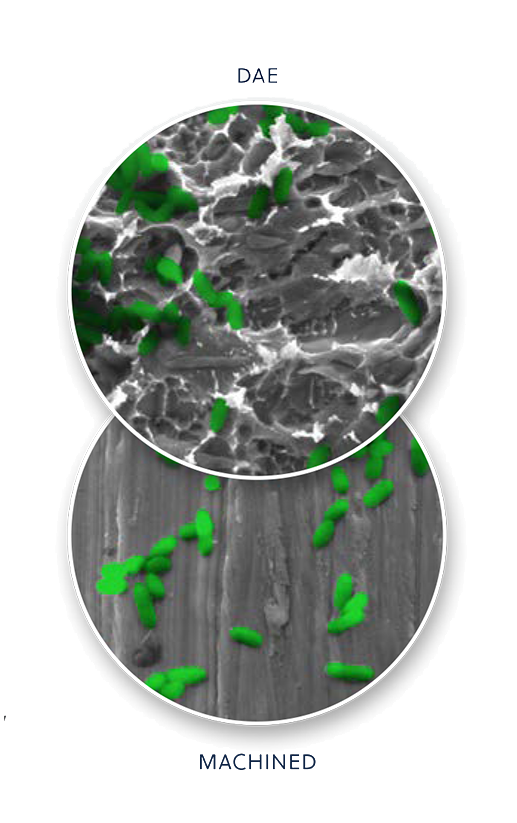

- Coronal DAE Surface - No increased risk of peri-implantitis compared to machined titanium. Better crestal bone maintenance than machined titanium in the coronal region.1-5, 12-14

- MTX Surface - High osteoconductive potential and over two decades of clinical success.1, 7, 8

TSX Dental Implant Clinical Results

The increased prevalence of peri-implantitis and demand for immediacy protocols were the two main rationales behind ZimVie’s new TSX Implant design.

The TSX Implant incorporates several design elements with a long history of clinical use established by Screw-Vent® and TSV Implants. The origins of these design features and understanding of their clinical rationale and evidence provide historical context for the evolution of the TSX Implant.

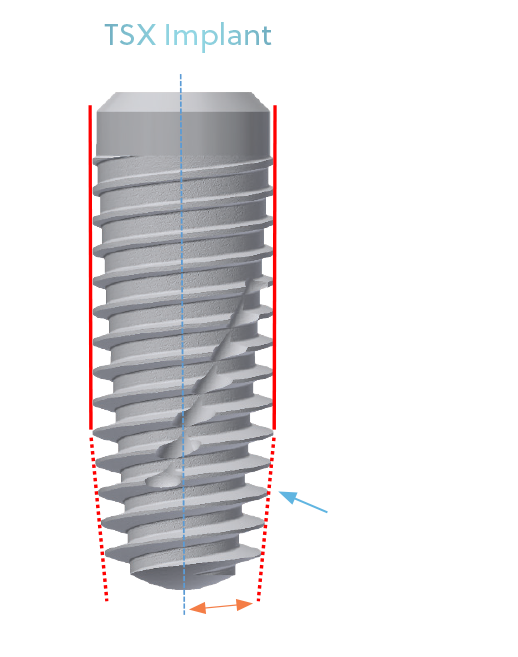

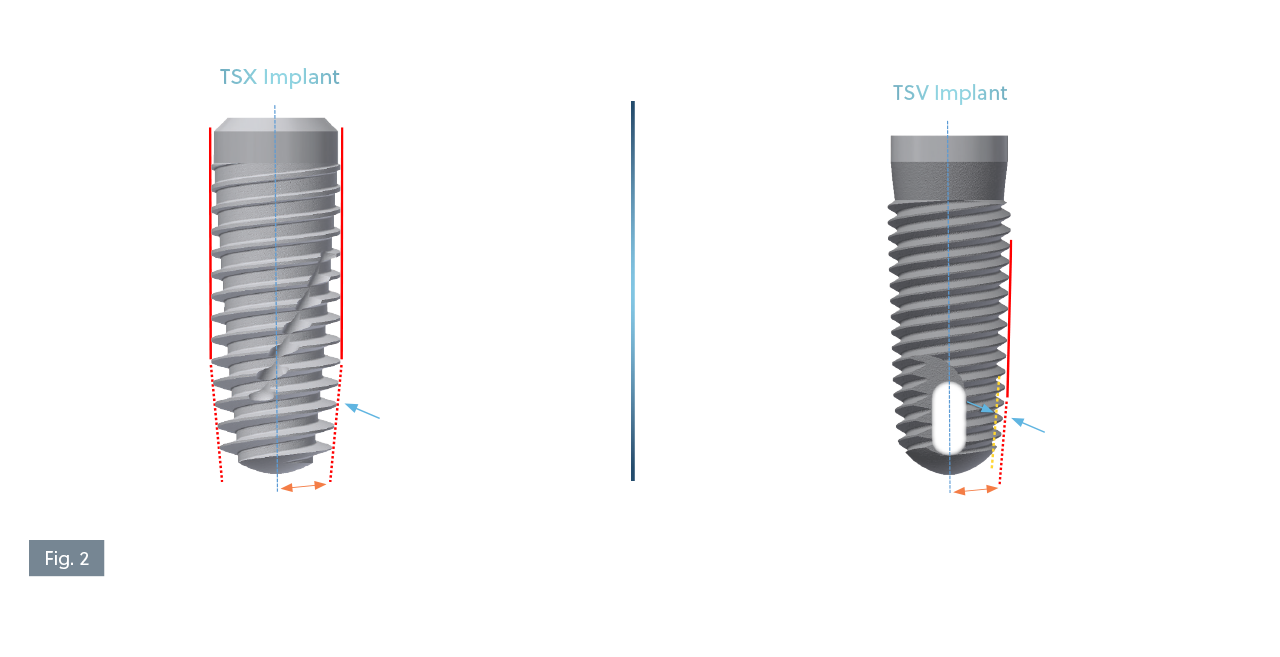

The new TSX Implant includes unique design features to enhance implant primary stability by increasing the surface area of the implant that comes into initial contact with bone and providing a progressive increase of torque as the implant is inserted. This will help achieve high stability and sufficient insertion torque to instill confidence from tactile feel of stability during placement while not generating excessive insertion torque values.1

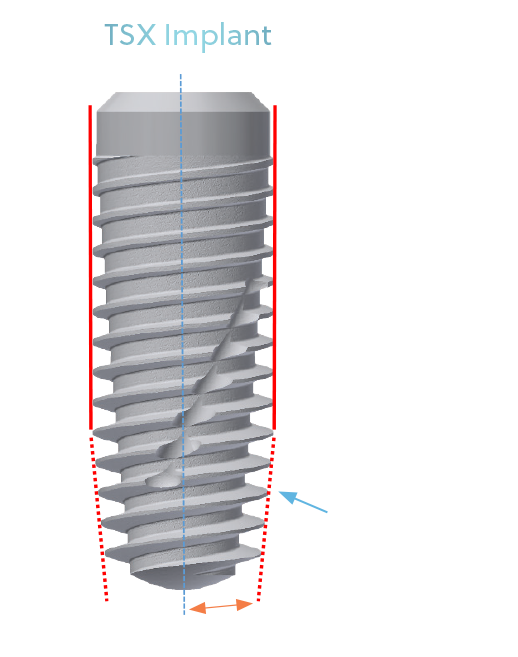

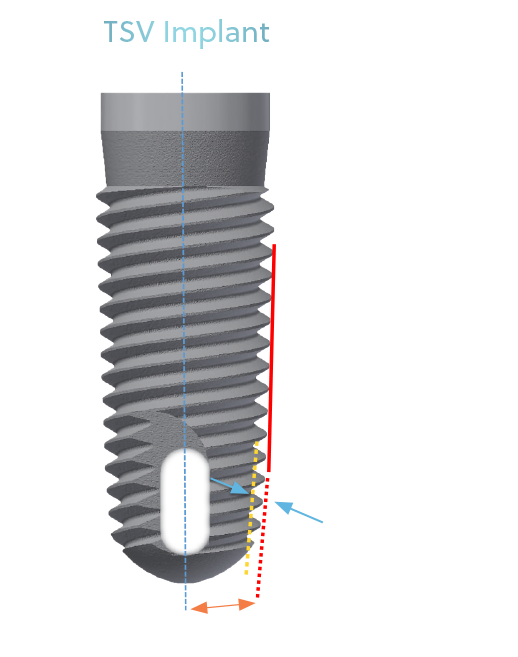

Fig. 2 CAD model of (top) TSX 4.7mm x 13mm and (bottom) TSV 4.7mm x 13mm. The yellow lines show the minor diameter taper and the red lines show the major diameter taper. The blue arrows point at the depth of the threads.

Fig. 2 CAD model of (top) TSX 4.7mm x 13mm and (bottom) TSV 4.7mm x 13mm. The yellow lines show the minor diameter taper and the red lines show the major diameter taper. The blue arrows point at the depth of the threads.

Xcellerated Workflow

Digital Dentistry Solutions